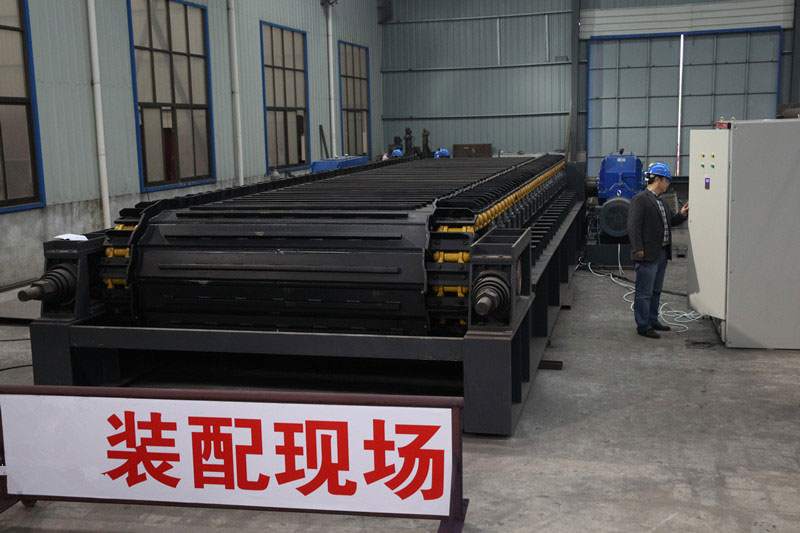

Heavy plate feeder,Heavy plate feeder conveyors,Plate conveyors

Description

Heavy plate feeder conveyors is my company in the summary of many years engaged in conveying equipment design, manufacture, service experience, based on the extensive absorption and application of modern advanced technology independent research and development of new and efficient transport equipment. The equipment is mainly used in a warehouse and funnel with a certain warehouse under the pressure, a short distance even, a variety of bulk materials to a variety of bulk materials, crushing, screening and transportation equipment, especially for coarse material feeding and Short-distance delivery.

【Feed size】: 0-1600mm

【Production capacity】: 150-1000t / h

Application:

Metal mining, engineering construction, cement industry and coal industry.

Product advantages

Equipment strength

Equipment using standard tank chain drive, high strength, large pull, no lubrication, small error, long service life without using maintenance; carrier plate made of alloy steel welded, high strength, long service life.

Installation and maintenance is simple

Vertical cross reducer, floating suspension installation, easy maintenance; spindle and sprocket connections are used expansion joints without key connection, not only the strength, but also easy disassembly, easy maintenance.

run smoothly

Adopt frequency conversion motor to drive, easy to operate and control, start and adjust more stably, feed evenly and accurately, feeding speed can be linked with the host to achieve automatic feedback to the material, to ensure the ability of follow-up equipment to achieve maximum efficiency; tensioning device buffer design, Reduce equipment vibration impact.

Wide range of applications

Feeding granularity, can be directly installed in the raw material warehouse, can withstand a larger warehouse pressure; subject to the material size of the composition, temperature, viscosity, frost, rain, snow or ice material less affected, environmental adaptability, can be poor Operating environment conditions.

Plate feeder conveyors Definitions

Plate feeder conveyors is generally divided into heavy, medium and light three, is the feed used by the beneficiation plant

Light plate feeder conveyors to the continuous feeding machine, suitable for short-distance feed to the feed size of 160mm below the bulk material. In mines, processing plants, chemicals, cement, building materials and other departments, widely used for crushing, transportation and other machinery from the storage silos for continuous feeding. Can be installed horizontally, but also inclined installation, the maximum tilt up to 20 degrees. General to adapt to the loose density of less than 1200kg / m3, block weight less than 140kg, the temperature of 350 ℃ below the material.

Medium-sized plate feeder conveyors intermittent feeding machinery, suitable for short-distance feed to the feed size of 400mm below the bulk material. In mines, processing plants, chemicals, cement, building materials and other departments, widely used in crushing storage, transportation and other machinery for intermittent intermittent feeding. Can be installed horizontally, but also inclined installation, the maximum tilt up to 20 degrees. General to adapt to the loose density of less than 12400kg / m3, block weight less than 500kg, the temperature below 400 ℃ material.

Heavy plate feeder conveyors is an auxiliary equipment for transportation machinery. The machine is used for crushing and grading workshop and cement, building materials and other departments of large-scale concentrator as continuous and uniform feeding to primary crusher as silo, and also for short-distance conveying Granularity and the proportion of larger materials. Can be installed horizontally, but also inclined installation, the maximum inclination of 12 degrees. In order to avoid the material hit directly to the feeder, the required storage bin does not appear empty state.

Various types of plate feeder conveyor sub-transmission by transmission and left-type transmission, along the material running direction, the right side of the transmission system for the right-type transmission, on the contrary for the left-type transmission.

working principle

The working principle of the plate feeder is that the power of the motor is rotated by the coupling and reducer to drive the sprocket shaft, and the chain plate and the chain are meshed to drag the chain plate to make continuous linear motion. The chain plate is supported by a support wheel and a carrier wheel mounted on the rack, and the chain and the sprocket are correctly meshed by adjusting the tensioning device to complete the purpose of material delivery.